Underground Mining Structure (UMS)

View our Underground Mining Tyre Range

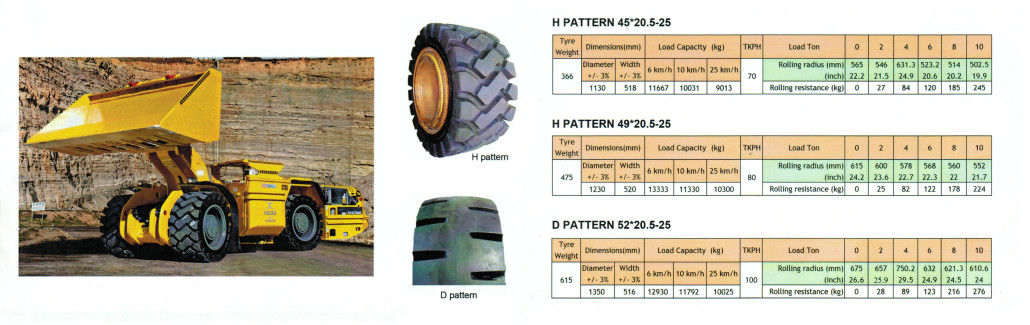

Earthmover tyres for surface mining and underground mining need to withstand some of the most difficult OTR conditions. Intensive use, long operating hours and harsh, rocky conditions demand a tough tyre.

TY have developed an industry specific structure and compound especially for the underground coal mining industry. The newly introduced UMS (Underground Mining Structure) tread pattern along with rubber compound modifications has resulted in improved traction and improved tread wear without chunking, whilst providing operator comfort. TY tyres are resilient in construction and therefore have no air, making TY the safest maintenance-free option without downtime, available on the market. TY tyres can be mounted on existing wheels.

Underground Application Tyre Benefits:

• Soft centre compound provides the operator with a pneumatic like tyre ride.

• Sidewall aperture are available to enhance the operator comfort and aid steering response.

• Special construction and compound specifically designed for the arduous tasks of the underground.

• As the TY is a resilient tyre, there is no risk of blow outs.

• No punctures, therefore no downtime

• No air so they are virtually maintenance free

• Press fit to existing rims.

Industrial tyres for mining

In order to meet the needs of Australian mines, industrial mining tyres must be purpose built for use in harsh condition. Tyres commonly used in mining operations include:

- Solid industrial tyres

- Pneumatic industrial tyres

- Underground Mining Structure (UMS) tyres

One of the leading tyre brands of mining tyres is the BKT Earthmax range. They provide excellent durability and traction in off-road condition, making them ideal for mining. Another leading brand is TY Cushion Tire, the side-wall aperture tyre structure is commonly used for mining loaders.

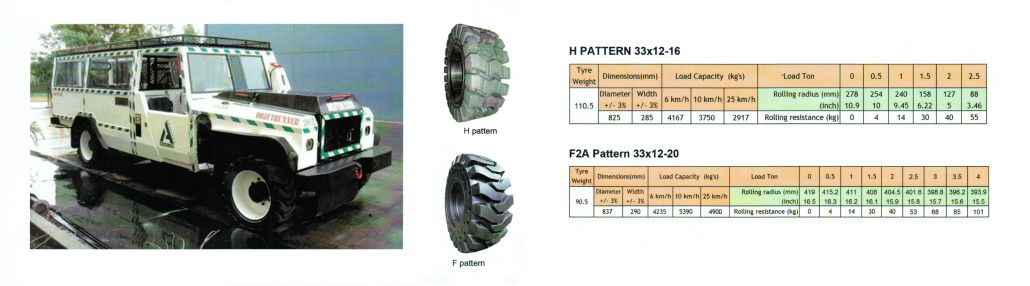

Personnel Carrier / Shuttle Tyre

TY offers two options for use on Personnel Carriers both providing an airless, puncture proof, safe alternative to pneumatic tyres. The TY H pattern offers exceptional wearing capabilities with resilient construction and block style tread. The F pattern offers an airless resilient construction with Apertures which add to the ride comfort.

Tyres For The Harshest Industrial Applications

Mining operations require the large-scale use of vehicles and machinery. Mining vehicles are the largest industrial vehicles commonly in use in Australia and they require enormous tyres to match.

TFI highly recommends the BKT brand as a major part of its underground mining tyre range.

The BKT Underground mining tyre range includes:

– EARTHMAX SR 53: an All Steel radial tyre specially designed for loaders, dozers and low profile dump trucks (LPDT) operating in severe rocky conditions, including underground operations and scrap yards.

– EARTHMAX SR 55: an All Steel radial tire specially designed for loaders, dozers and load haul dumps operating in the most severe underground mining operations, and at scrapyards.

– EARTHMAX SR 49 M: an All Steel radial tyre with a special non-directional pattern designed for load haul dumps (LHD), low profile dump trucks (LPDT), loaders and dozers operating in severe rocky conditions primarily in underground mining.

– EARTHMAX SR 42: an all steel radial OTR tyre specially engineered for haul trains in mining applications.