Agricultural Rubber Tracks

High-quality Agricultural Rubber Tracks

TFI brings you the finest range of rubber tracks made for Australian conditions, built for Friction Drive Agricultural tractors. Known for their durability and superior performance, the specialized rubber tracks can be used for tractors for farms or anything related to the field of agriculture. If you are looking for quality rubber tracks for agricultural tractors, you have come to the right place. Check out our collection to discover some of the best tracks to optimize the performance of your application.

Leading Supplier Of Agricultural Rubber Tracks

We are aware of the operating environments and understand the importance of equipping your agricultural vehicles with the right rubber tracks. We take immense pride in supplying rubber tracks that enhance the performance of your tractor and improve efficiency.

Some of the world-class features of our tracks are:

- Highly tested and vulcanized rubber tracks that withstand heavy usage and intense climatic conditions.

- Designed tracks that have wide and deep tread lugs to prevent any work time skidding

- A maintained 41 carcass thickness and a 4-ply structure that ensure a comfortable ride for the operator at any point of time.

- On average, we have between 18-30% more tread surface area on our track per metre than other competitor brands

- Usage of 5.1 mm high tensile main cables to prevent continuous stretching of the track. This is to reduce power loss and fuel usage.

- High flotation capacity to allow machines to work in wet weather conditions in the soil.

All these features paired with our excellent warranty services that extend up to 4 years, makes TFI just the place to pick up your replacement tracks.

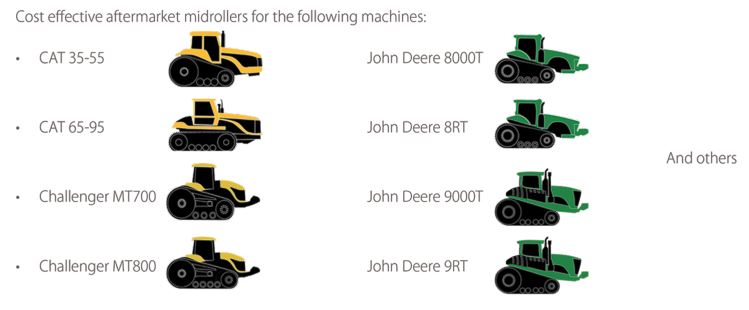

The products we have at TFI provide ag rubber tracks for the following machines:

- AGCO Challenger MT700 and MT800 model tractors

- John Deere 8000T, 9000T, 8RT and 9RT model tractors

Quality Rubber Tracks At Affordable Prices

All our rubber tracks for farm tractors are competitively priced and you can be sure of receiving top-quality rubber tracks. To find out more about our costs and our products, do not hesitate to get in touch with us at TFI. You can give us a call on 1300 916 556 or email us at [email protected]

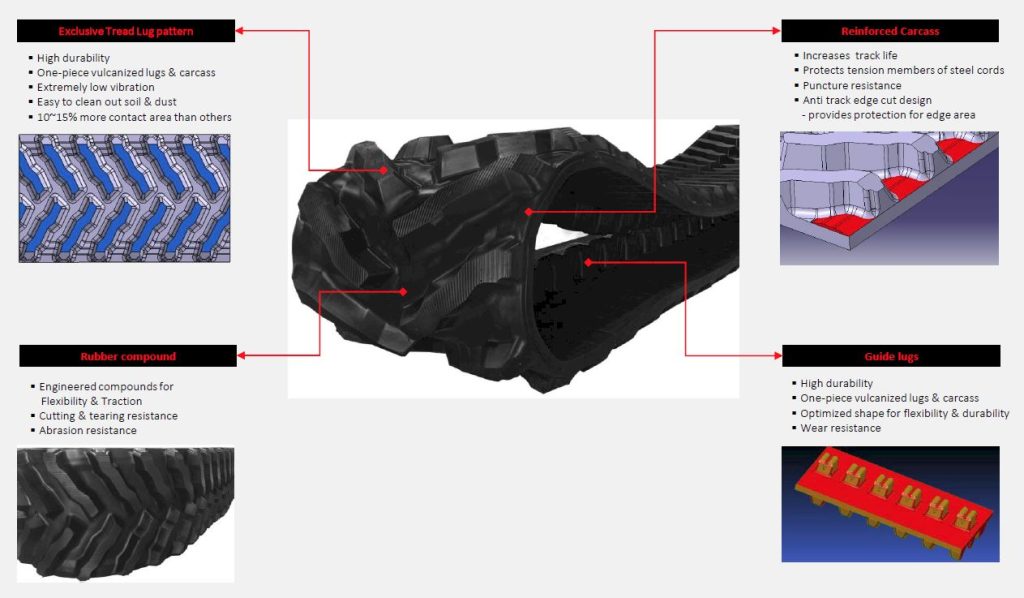

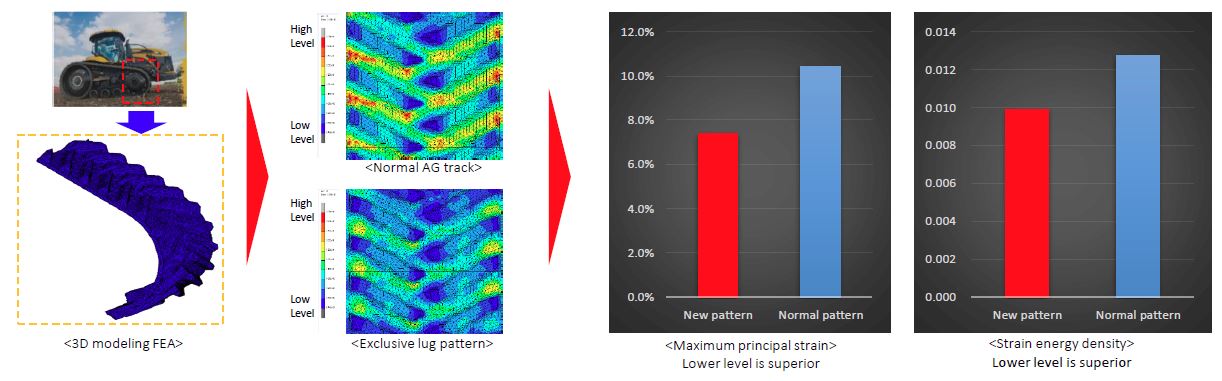

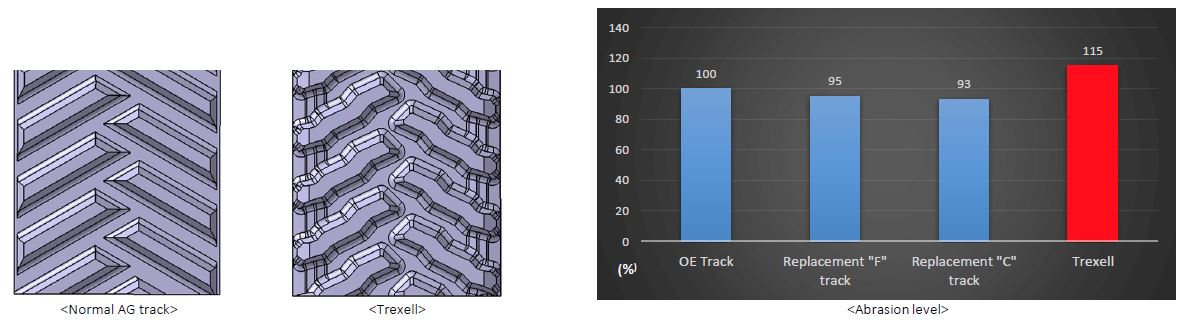

Exclusive Tread Lug pattern

Exclusively engineered tread lug pattern is structurally remarkable in comparison with Normal AG track. It provides resistance to cutting & tearing through low level of stress and vibration.

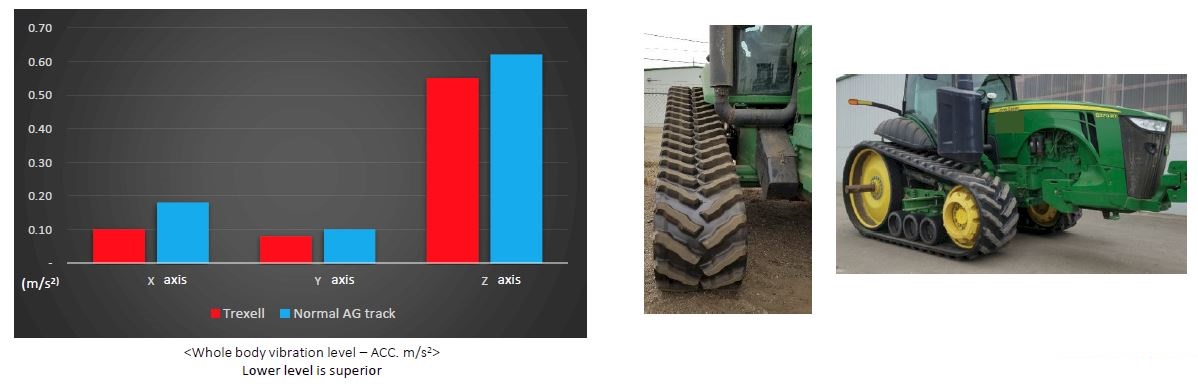

Low Vibration

The tread, specialised in low and high velocity of driving on diverse conditions of loads, cuts down more than 15% level of vibration. The track enhances comfort in driving and extends the life span of machine compared to Normal AG track.

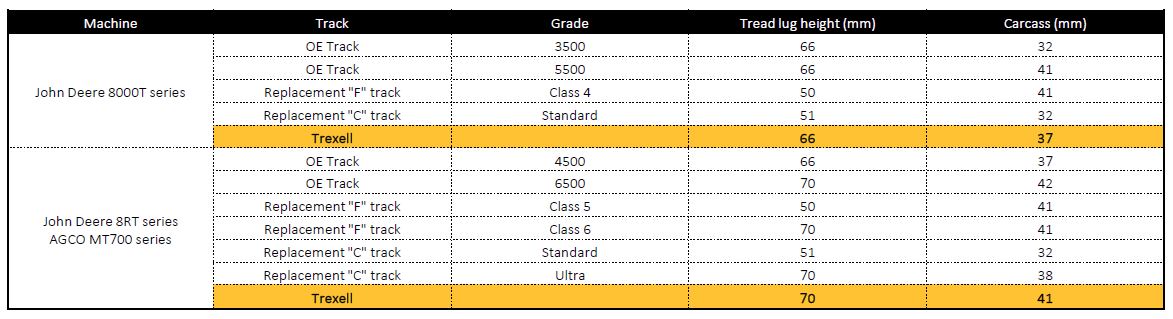

Reinforces tread lugs and carcass

Trexell guarantees a long life span of machines with its best grade in height of tread lug and thickness among other replacement tracks in the market.

Resistance to abrasion & wear

Trexell is equipped with unique form of tread, increasing contact area compared to Normal AG track. It also contains 15% higher abrasion performance by the exclusively researched compound technique.

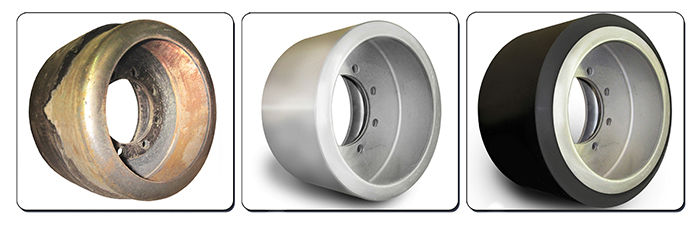

WHEEL REMANUFACTURING SERVICE:

Want to significantly reduce the cost of replacing mid-rollers?

Contact TFI to make arrangements to have your worn mid-rollers sent in to be reconditioned with high performance polyurethane.

Once the wheels are received, they will be stripped of all the old rubber compound and the rims will be cleaned and prepared for the retreading process.

The cleaned wheels will then be retreaded with high performance polyurethane and shipped back for installation.

- No Bond Failures Guaranteed – Proprietary bonding technology that resists heat and shear force to prevent debonding

- Longest Wear-life – Polyurethane compound engineered to generate less heat, reduce chunking, and provide the highest cut & tear resistance

- Resist the Elements – Unlike rubber, OUR polyurethane is resistant to Oils, UV, Weak Acids, Diesel Fuel, Moisture and more

- Extend Rubber Track Life – Lower operating temperatures reduce rubber track deterioration. Tough polyurethane will not capture debris and score the track.

| PU MIDROLLERS | ||

| CAT Challenger | 35/45/65 | PU Midroller Challenger 35/45/55 (Narrow) |

| CAT Challenger | 65/95 | PU Midroller Challenger 65/95 (Wide) |

| AGCO Challenger | MT700 | PU Midroller Challenger MT700 (Wide) |

| AGCO Challenger | MT800 | PU Midroller Challenger MT800 (Wide) |

| John Deere | 8RT | PU Midroller John Deere 8RT (Wide) |

| John Deere | 9000T | PU Midroller John Deere 9000T (Wide) |

| John Deere | 9RT | PU Midroller John Deere 9RT (Wide) |

GENERAL GUIDELINES FOR MIDROLLER REPLACEMENT

- More than 1/3 of the total rubber is missing around the entire midroller

- All the rubber is missing at any point all the way across the midroller

- Any flat spots are seen which may indicate midroller stopped turning

Note: you should always change midrollers & idlers in pairs to promote equal down pressure from the axle to the track.

For more information, give us a call 1300 916 556 or [email protected]

Tradefaire is your premier destination for high-quality agricultural rubber tracks in Australia. As the accredited Australian distributor of leading tyre and track brands, we have been delivering the world’s best tyre brands since 1992. With over 20 years of experience, a proven distribution network, and a commitment to superior quality, we are your trusted partner for all your agricultural track needs.

Rubber Tracks for Farm Tractors

Our range of rubber tracks for farm tractors is designed to enhance the efficiency and performance of your agricultural machinery. Made from state-of-the-art premium materials, our tracks deliver significant cost reductions compared to any Tier 1 manufactures. With our tracks, you can rest assured that your farm tractors will operate smoothly and efficiently, minimising downtime and maximising productivity.

The Importance of Quality Agricultural Tracks

In the agricultural sector, the importance of quality agricultural tracks cannot be overstated. These tracks are the foundation of your farm machinery, providing traction, stability, and durability in the challenging conditions of the field. Tradefaire understands that inferior tracks can lead to increased downtime, maintenance costs, and reduced productivity, which is why we are committed to offering only the best products from leading brands.

Enhanced Performance and Durability

One of the primary reasons why quality agricultural tracks are essential is their role in enhancing the performance and durability of your farm machinery. Our tracks are designed to withstand the rigours of agricultural work, providing superior traction even in the most challenging conditions. This ensures that your machinery can operate efficiently, reducing the risk of breakdowns and costly repairs.

Minimised Downtime and Maintenance Costs

Inferior tracks are more prone to wear and damage, leading to increased downtime and maintenance costs. By investing in quality agricultural tracks from Tradefaire, you can minimise downtime and maintenance costs, ensuring that your farm machinery remains operational when you need it most. Our tracks are made from high-quality materials that are resistant to cuts, tears, and abrasions, ensuring long-lasting performance in the field.

Improved Productivity

Quality agricultural tracks can also improve the overall productivity of your farm operations. By providing superior traction and stability, our tracks allow your machinery to operate more efficiently, reducing the time and effort required to complete tasks. This can lead to increased productivity and profitability for your farm, ensuring that you stay ahead of the competition.

Long-Term Cost Savings

While quality agricultural tracks may require a higher initial investment, they can provide significant long-term cost savings. By reducing downtime, maintenance costs, and improving productivity, our tracks offer excellent value for money. With Tradefaire’s tracks, you can rest assured that your investment will pay off in the form of improved performance, durability, and efficiency for years to come.

The Benefits of Our Rubber Tracks for Agricultural Tractors?

We take pride in offering high-quality rubber tracks that are specifically designed to enhance the performance of agricultural tractors. Our tracks offer a range of benefits that can help improve efficiency and productivity on the farm. Here are some of the key benefits of choosing our rubber tracks for your agricultural tractors:

Improved Traction: One of the primary benefits of our rubber tracks is improved traction. The unique tread pattern and rubber compound of our tracks provide superior grip on various surfaces, including wet and slippery terrain. This improved traction allows your tractors to operate more efficiently, even in challenging conditions.

Reduced Ground Compaction: Another significant benefit of our rubber tracks is reduced ground compaction. Unlike traditional tires, which can compact the soil and damage crops, our rubber tracks distribute the weight of the tractor more evenly, reducing the impact on the ground. This can help improve soil health and crop yields over time.

Increased Stability: Our rubber tracks are designed to provide increased stability for your agricultural tractors. The wider footprint of our tracks helps distribute the weight of the tractor more evenly, reducing the risk of tipping over on uneven terrain. This increased stability can help improve safety and efficiency on the farm.

Resistance to Cuts, Tears, and Abrasions: Our rubber tracks are highly resistant to cuts, tears, and abrasions, ensuring long-lasting performance in even the most demanding conditions. This durability reduces the need for frequent replacements, saving you time and money in the long run.

Enhanced Performance and Efficiency: Overall, our rubber tracks are designed to enhance the performance and efficiency of your agricultural tractors. By providing improved traction, reduced ground compaction, and increased stability, our tracks can help your tractors operate more efficiently, saving you time and money.

A Comprehensive Range of AG Rubber Tracks

Tradefaire takes pride in offering a comprehensive range of AG rubber tracks tailored to meet the diverse needs of agricultural machinery. Whether you require tracks for your tractor, harvester, or other farm equipment, we have the perfect solution for you. Our extensive range of tracks is designed to fit a wide range of makes and models, ensuring compatibility and optimal performance for your agricultural machinery.

Tractor Tracks: Our tractor tracks are designed to provide superior traction, stability, and durability for your agricultural tractors. Whether you’re working in wet, muddy conditions or on rough, uneven terrain, our tracks are up to the task, ensuring that your tractor can operate efficiently in any environment.

Harvester Tracks: Harvesters require tracks that can withstand the rigors of heavy-duty harvesting operations. Our harvester tracks are designed to provide the necessary traction and stability to ensure that your harvester can navigate through fields with ease, even when fully loaded with crops.

Other Farm Equipment Tracks: In addition to tractor and harvester tracks, we also offer tracks for a variety of other farm equipment, including loaders, sprayers, and tillers. Our tracks are designed to fit a wide range of equipment, ensuring that you can find the perfect track for your specific needs.

Compatibility and Performance: Our tracks are designed to be compatible with a wide range of makes and models of agricultural machinery, ensuring that you can find the perfect track for your equipment. Additionally, our tracks are designed to provide optimal performance, ensuring that your machinery operates efficiently and effectively in any environment.

Durability and Reliability: We understand that agricultural machinery is subjected to harsh conditions, which is why we ensure that our tracks are made from high-quality materials that are durable and reliable. Our tracks are designed to withstand the rigors of agricultural work, ensuring that they provide long-lasting performance and value for money.

Leading AG Tracks Suppliers

As a leading supplier of AG tracks in Australia, Tradefaire is proud to offer superior products and exceptional customer service. Our team of experts is dedicated to helping you find the right track for your agricultural machinery, ensuring that you get the best possible performance and value for money. With our proven track record and commitment to quality, we are the preferred choice for AG tracks in Australia.

Tradefaire vs Other Providers

Aspect | Tradefaire | Other Providers |

|---|---|---|

Product Range | Offers a comprehensive range of high-quality AG tracks. | May offer a limited selection of tracks with varying quality. |

Quality Assurance | Tracks are made from premium materials for durability. | Quality may vary, and materials may not be as durable. |

Customer Support | Provides expert advice and support for all customers. | Customer support quality may vary between providers. |

Installation Services | Offers installation services to ensure proper fitment. | May not offer installation services, leaving it to the customer. |

Pricing | Competitive pricing with value for money. | Pricing may vary, with some providers offering higher prices. |

Warranty | Offers a warranty on tracks for peace of mind. | Warranty offerings may vary among providers. |

Experience | Over 20 years of experience in the industry. | Experience levels may vary among providers. |

Customer Satisfaction | Has a proven track record of customer satisfaction. | Satisfaction levels may vary depending on the provider. |

Distribution Network | Has a proven local, national, and international network. | Network may not be as extensive, leading to longer wait times. |

Frequently Asked Questions

What are agricultural rubber tracks, and how do they differ from other types of tracks?

Agricultural rubber tracks are continuous tracks made of rubber that are used on agricultural machinery, such as tractors and harvesters. They differ from other types of tracks, such as steel tracks, in that they provide better traction, reduce ground compaction, and offer a smoother ride.

What are the benefits of using agricultural rubber tracks?

Agricultural rubber tracks offer several benefits, including improved traction, reduced ground compaction, increased stability, and enhanced manoeuvrability. They also provide a smoother ride, reduce soil damage, and improve fuel efficiency.

Are agricultural rubber tracks suitable for all types of agricultural machinery?

Agricultural rubber tracks are designed to fit a wide range of agricultural machinery, including tractors, harvesters, sprayers, and more. They are available in various sizes and configurations to suit different makes and models of equipment.

How do I choose the right agricultural rubber tracks for my equipment?

When choosing agricultural rubber tracks, consider factors such as the size and weight of your equipment, the type of terrain you’ll be working on, and your specific needs and preferences. It’s also important to ensure that the tracks are compatible with your machinery.

Are agricultural rubber tracks easy to install and maintain?

Agricultural rubber tracks are relatively easy to install and maintain, especially compared to other types of tracks. They require regular cleaning and inspection to ensure optimal performance and longevity.

What are the differences between OEM and aftermarket agricultural rubber tracks?

OEM (Original Equipment Manufacturer) agricultural rubber tracks are made by the same manufacturer as your equipment and are designed to meet the original specifications. Aftermarket tracks are made by third-party manufacturers and may offer cost savings but may not always meet the same quality standards as OEM tracks.

How long do agricultural rubber tracks typically last?

The lifespan of agricultural rubber tracks can vary depending on factors such as the quality of the tracks, the type of terrain they are used on, and how well they are maintained. On average, agricultural rubber tracks can last anywhere from 1,000 to 3,000 hours or more.

Can agricultural rubber tracks be repaired if damaged?

Yes, agricultural rubber tracks can often be repaired if they are damaged. Minor damage, such as cuts or tears, can usually be repaired using a patch kit. However, more severe damage may require the replacement of the entire track.

Are there any special considerations for using agricultural rubber tracks in wet or muddy conditions?

When using agricultural rubber tracks in wet or muddy conditions, it’s important to clean them regularly to prevent mud and debris buildup. It’s also a good idea to use tracks with a deep tread pattern for better traction in these conditions.

What are some common misconceptions about agricultural rubber tracks?

One common misconception is that agricultural rubber tracks are only suitable for use in certain types of terrain. In reality, modern agricultural rubber tracks are designed to perform well in a wide range of conditions, making them a versatile choice for farmers and agricultural workers.